Hello, how can we help?

Here at 15Hatfields we’re passionate about operating our award-winning venue as sustainably as possible. We only work with partners who mirror our enthusiasm and sustainable ethos.

Our Deputy General Manager, Joe Harris, recently visited our commercial linen provider, Johnsons Stalbridge (JSG), to learn more about their Vision 2030 Commitments.

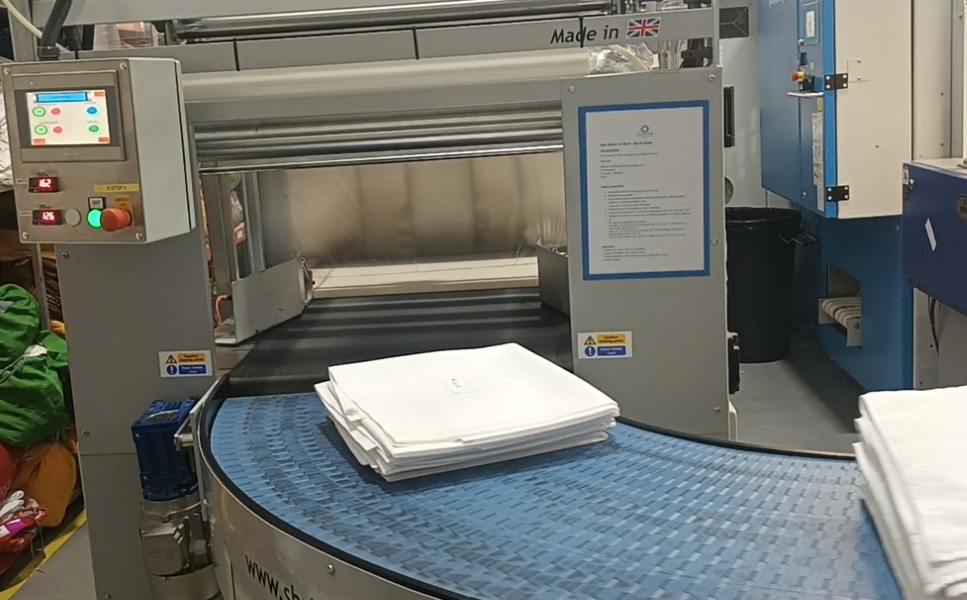

Through their rental and laundry service, JSG supply fresh linen for fine dining and catered events hosted at our venue. Joe cycled to their facility in Southall where our tablecloths, napkins and tea towels follow a sophisticated journey as they're laundered to perfection.

Catching up with the Southall team, Joe learned more about JSG's progress towards their 2030 commitments including innovations in textiles recycling, water recovery and sustainable production.

Always innovating

Given the water-intensive nature of laundry and the scale of their operations, JSG have been working to reduce water consumption intensity. In 2021, their total water consumption for their 37 facilities came in at 1.7 million cubic metres, which is enough to fill 680 Olympic swimming pools!

With the support of the Carbon Trust, JSG introduced water recovery technology at their site in Shaftesbury. By using this technology to treat processed water, the Shaftesbury team are able to re-use up to 80% of water at their facility.

Across 2022, JSG achieved a 10% reduction in water usage intensity. Given the positive results of the water recovery project, it will be great to see what further reductions will be possible once this technology is rolled out across their other facilities. A new project is also in the works at JSG to trial a technology that could potentially remove water discharge completely.

Promoting sustainable production methods

While following the complex journey of our linen around JSG’s laundry facility, we discussed where they source their linen from, and their continued efforts to address the environmental impacts of cotton production.

Nearly 75% of freshwater resources are used in crop or livestock production. Being the most widespread profitable non-food crop, cotton has contributed significantly to water scarcity through unsustainable methods of production. Traditional methods have included the use of agrochemicals (notably pesticides) which has led to biodiversity loss and environmental degradation.

JSG is a member of the Better Cotton Initiative, which was developed from a roundtable discussion led by WWF in 2005. Better Cotton works with farmers to map water resources, improve soil quality, implement efficient irrigation practices, reduce synthetic pesticide use, and engage in community action. This work helps to not only improve yields but to reduce pollution, protect biodiversity and conserve resources in farming communities.

Initiatives like Better Cotton demonstrate the importance of collaboration when it comes to putting sustainability principles into practice on a global scale. It now has over 2,500 members working across the cotton industry.

Prolonging the lifecycle of the linen

For venues looking to source linen with sustainability in mind, there are a few key considerations. Firstly, the quality and durability of the material. Secondly, finding a professional laundry service that takes care to prolong the lifecycle of the linen. Working with JSG to keep our linen in use for as long as possible is important to us – particularly as textiles are notoriously difficult to recycle!

Natural fibres can’t be infinitely recycled – each time the fibres lose some of their length, strength and durability. As such, recycled cotton tends to be blended with other fibres such as polyester. Many recycling facilities currently lack the resources to process textiles due to the complexity of separating blended fabrics.

To overcome this obstacle, JSG partnered with the Textile Services Association to explore a technology which enables the separation of polycotton and polyester. As a result, they’ve transitioned to recycled polyester in their workwear collection – helping to both save materials from landfill and reduce further production of synthetic fibres which rely on the extraction of petroleum.

When it comes to transitioning to fully sustainable fabrics however, there are still significant hurdles to overcome in the textiles industry. Unfortunately, recycling synthetic fabrics doesn’t provide a solution to the shedding of microplastics. Estimates suggest between 16 and 35% of microplastics released to oceans globally originate from the washing of synthetic textiles.

It will be great to see how JSG’s research into natural fibre recycling progresses. The team are currently undertaking a number of feasibility projects to bring recycled cotton fibres back into the textile manufacturing process.

In the meantime, the lifecycle of the linen is extended through JSG’s work with local charities. The Southall team, for example, have donated over 800 chef jackets to The Clink Charity which supports rehabilitation.

Measuring the impacts

Running a sustainable venue means looking at both the social value and environmental impacts of our operations, and JSG are just one of many sustainability conscious companies that we work alongside. It’s important to us here at 15Hatfields that our suppliers join us in giving back to the community in more ways than one. Within our sustainability hub, you can learn more about our partners in sustainability as well as the community initiatives championed by our team.